China Best Sales Kc-3012 Sprocket Roller Chain Coupling Rigid Shaft Coupling Air Compressor Parts

What is Kc-3012 Sprocket Roller Chain Coupling Rigid Shaft Coupling Air Compressor Parts

Kc-3012 Sprocket Roller Chain Coupling Rigid Shaft Coupling Air Compressor Parts are used to join two pieces of rotating equipment while permitting various degrees of misalignment or end movement or both. This product is manufactured using high-quality materials and advanced technology. Our product is suitable for various industrial applications and can withstand high temperatures, high torque, and high-speed operations. Proper installation and maintenance of this product can lead to reduced downtime and maintenance costs.

The Advantages of Kc-3012 Sprocket Roller Chain Coupling Rigid Shaft Coupling Air Compressor Parts

High-Quality Materials

We use only the highest quality materials in our production process to ensure that our products meet the highest industry standards. Our Kc-3012 Sprocket Roller Chain Coupling Rigid Shaft Coupling Air Compressor Parts are manufactured using the latest technology and high-quality materials to ensure that they are durable and reliable.

Advanced Technology

Our Kc-3012 Sprocket Roller Chain Coupling Rigid Shaft Coupling Air Compressor Parts are manufactured using advanced technology to ensure that they are of the highest quality and meet the highest industry standards. Our products are designed to withstand high temperatures, high torque, and high-speed operations, making them suitable for a wide range of industrial applications.

Reduced Downtime and Maintenance Costs

Proper installation and maintenance of our Kc-3012 Sprocket Roller Chain Coupling Rigid Shaft Coupling Air Compressor Parts can lead to reduced downtime and maintenance costs. Our products are designed to be durable and reliable, which means that they will require less maintenance and repair over time.

Our Other Products and Services

Our company specializes in supplying various industrial products, such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We offer high-quality products at preferential prices with thoughtful services. Customers are welcome to customize their orders with drawings and samples.

Frequently Asked Questions

1. What are Kc-3012 Sprocket Roller Chain Coupling Rigid Shaft Coupling Air Compressor Parts?

Kc-3012 Sprocket Roller Chain Coupling Rigid Shaft Coupling Air Compressor Parts are used to join two pieces of rotating equipment while permitting various degrees of misalignment or end movement or both. They are manufactured using high-quality materials and advanced technology to ensure that they are durable and reliable.

2. What are the advantages of Kc-3012 Sprocket Roller Chain Coupling Rigid Shaft Coupling Air Compressor Parts?

Kc-3012 Sprocket Roller Chain Coupling Rigid Shaft Coupling Air Compressor Parts are made of high-quality materials and advanced technology, making them durable and reliable. They are designed to withstand high temperatures, high torque, and high-speed operations, making them suitable for a wide range of industrial applications. Proper installation and maintenance of these parts can lead to reduced downtime and maintenance costs.

3. What other industrial products does your company supply?

Our company supplies various industrial products, such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more.

4. What is your company’s pricing policy?

Our company offers high-quality products at preferential prices. We believe that our customers should have access to high-quality industrial products at affordable prices.

5. Do you offer customization services?

Yes, we offer customization services for our products. Customers are welcome to submit drawings and samples to customize their orders to their exact specifications.

All the content of this page is from the Internet. The content is only used as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Rigid Shaft Coupling

Rigid shaft coupling is widely used in various fields due to its excellent performance characteristics. Firstly, it has high torque transmission capacity, which can ensure the stable operation of the equipment. Secondly, the rigidity of the coupling effectively improves the accuracy of the transmission. Thirdly, the structure of the coupling is simple, which makes it easy to install and maintain. Finally, it has excellent resistance to wear and tear, and can effectively prevent the occurrence of vibration and noise during equipment operation.

Types and Characteristics of Rigid Shaft Coupling

Rigid shaft coupling can be divided into many types based on different materials and structures, such as metal couplings, elastomeric couplings, and composite couplings. Among them, metal couplings have the characteristics of high strength, high stiffness, and good wear resistance, making them suitable for high-precision transmission systems. Elastomeric couplings have the advantages of good elasticity, vibration damping, and energy absorption, making them suitable for systems with shock loads. Composite couplings are characterized by low noise, corrosion resistance, and lightweight, making them suitable for applications in precision machinery and aerospace.

Advantages of Rigid Shaft Coupling Made of Different Materials

Different materials of rigid shaft couplings have different advantages. Steel couplings have high strength, hardness, and wear resistance. Aluminum couplings have the advantages of light weight, corrosion resistance, and high heat dissipation. Stainless steel couplings have good rust and corrosion resistance, and are suitable for harsh environments. Titanium alloy couplings have excellent mechanical properties, such as high strength, light weight, and good corrosion resistance.

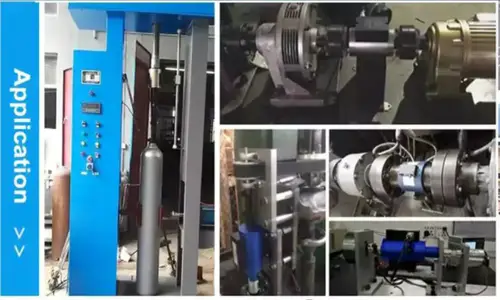

Application of Rigid Shaft Coupling

Rigid shaft coupling has a wide range of applications in various fields. In the Machining Equipment industry, it is used in machine tools, lathes, and drilling machines. In Conveyor Systems, it is used in belt conveyors, chain conveyors, and roller conveyors. In Robotic Systems, it is used in industrial robots and automatic assembly lines. In Pumps and Fans, it is used in centrifugal pumps and axial fans. In Power Transmission, it is used in gearboxes and reducers.

Future Development Trends and Opportunities of Rigid Shaft Coupling Products

The future development trend of rigid shaft coupling products is to improve the performance and reliability of the products, and to meet the needs of various industries for high-precision transmission systems. With the development of new materials and new technologies, the application fields of rigid shaft coupling will become wider and wider, and the market prospect will be very broad.

How to Choose a Suitable Rigid Shaft Coupling

When choosing a rigid shaft coupling, several aspects should be analyzed. Firstly, the torque requirements of the equipment should be considered. Secondly, the misalignment tolerance of the coupling should be consistent with the requirements of the equipment. Thirdly, the operational speed of the equipment should be taken into account. Fourthly, the environmental conditions of the equipment should be considered. Finally, the space constraints and installation requirements of the equipment should be analyzed comprehensively.

Summary

In summary, rigid shaft coupling is an important component in high-precision transmission systems. It has many excellent performance characteristics and can be made of different materials. Rigid shaft coupling has a wide range of applications in various fields such as Machining Equipment, Conveyor Systems, Robotic Systems, Pumps and Fans, and Power Transmission. In the future, with the development of new materials and new technologies, the market prospect of rigid shaft coupling products will be very broad.

Author: Dream