China Wholesaler Factory Custom Set Screw Two Piece Split Motor Rigid Shaft Coupling Air Compressor Portable

Product Description

The set screw two piece split motor rigid shaft coupling is a type of mechanical device used to connect two shafts together and provide rotary motion between them. The coupling is made of high-quality materials and is suitable for use in a wide range of industrial applications such as wind towers, nuclear power, railway, automotive industry, construction, and electronic industry. It comes in various types including hex bolts, flange bolts, hex head bolts, lag bolts, square bolts, eye bolts, u bolts, t bolts, counter sunk bolts, hex head nut, eye nut, dome nut, coupling nut, square nut, acorn nut, hex head cap screws, socket set screws, anchor screws, socket head screws, concrete screws, shoulder screws, threaded screws, machine screws, machine washers, flat washer, star washers, sealing washer, lock washer or custom size or type if required by customers.

The standard fasteners are manufactured according to ISO 4017, DIN933 DIN931 DIN934 DIN912 DIN603 DIN6923, GB5783, ASTM, ANSI, JIS, BS, and have a diameter range of M2-M100 and a length range of 5-5000mm. The bolts head type includes hex, square, round, hex flange, flat, T-head & triangular. The surface treatment includes Zinc Plated (Yellow, White, Blue, Black), Hop Dip Galvanized (HDG) phosphorization, Black Oxide, Geomet, Dacroment, anodization, Nickel plated, Zinc-Nickel plated, Brass Plated, Tin Plated, Black Plated, Copper Plated, Gold Plated and Salt fog test. The manufacturing process includes wire drawing, cold heading, insert tapping, heat treatment, surface plating, inspection, and packing. The tolerance ranges from +/-0.01mm to +/-0.05mm.

We believe that our products’ quality is our lifeline, so we always choose the best materials to produce and make sure our fasteners’ quality is the best. We have a lot of stock in storage, making sure the short delivery time. We have the standard fasteners but also accept the non-standard custom. Welcome to contact us if you need any fasteners!

Frequently Asked Questions:

1. What is a set screw two piece split motor rigid shaft coupling?

A set screw two piece split motor rigid shaft coupling is a mechanical device used to connect two shafts together and provide rotary motion between them.

2. What are the applications of the set screw two piece split motor rigid shaft coupling?

The coupling is suitable for use in a wide range of industrial applications such as wind towers, nuclear power, railway, automotive industry, construction, and electronic industry.

3. What types of fasteners are available for the set screw two piece split motor rigid shaft coupling?

The set screw two piece split motor rigid shaft coupling comes in various types including hex bolts, flange bolts, hex head bolts, lag bolts, square bolts, eye bolts, u bolts, t bolts, counter sunk bolts, hex head nut, eye nut, dome nut, coupling nut, square nut, acorn nut, hex head cap screws, socket set screws, anchor screws, socket head screws, concrete screws, shoulder screws, threaded screws, machine screws, machine washers, flat washer, star washers, sealing washer, lock washer or custom size or type if required by customers.

4. What is the manufacturing process of the set screw two piece split motor rigid shaft coupling?

The manufacturing process includes wire drawing, cold heading, insert tapping, heat treatment, surface plating, inspection, and packing.

5. What is the tolerance range of the set screw two piece split motor rigid shaft coupling?

The tolerance ranges from +/-0.01mm to +/-0.05mm.

Other Products:

Our company mainly supplies various industrial products, such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, etc. We offer high-quality products, preferential prices, and thoughtful services. Customers are welcome to customize with drawings and samples.

All the content of this page is from the Internet. The content is only used as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Rigid Shaft Coupling

Rigid shaft coupling is widely used in various fields due to its excellent performance characteristics. Firstly, it has high torque transmission capacity, which can ensure the stable operation of the equipment. Secondly, the rigidity of the coupling effectively improves the accuracy of the transmission. Thirdly, the structure of the coupling is simple, which makes it easy to install and maintain. Finally, it has excellent resistance to wear and tear, and can effectively prevent the occurrence of vibration and noise during equipment operation.

Types and Characteristics of Rigid Shaft Coupling

Rigid shaft coupling can be divided into many types based on different materials and structures, such as metal couplings, elastomeric couplings, and composite couplings. Among them, metal couplings have the characteristics of high strength, high stiffness, and good wear resistance, making them suitable for high-precision transmission systems. Elastomeric couplings have the advantages of good elasticity, vibration damping, and energy absorption, making them suitable for systems with shock loads. Composite couplings are characterized by low noise, corrosion resistance, and lightweight, making them suitable for applications in precision machinery and aerospace.

Advantages of Rigid Shaft Coupling Made of Different Materials

Different materials of rigid shaft couplings have different advantages. Steel couplings have high strength, hardness, and wear resistance. Aluminum couplings have the advantages of light weight, corrosion resistance, and high heat dissipation. Stainless steel couplings have good rust and corrosion resistance, and are suitable for harsh environments. Titanium alloy couplings have excellent mechanical properties, such as high strength, light weight, and good corrosion resistance.

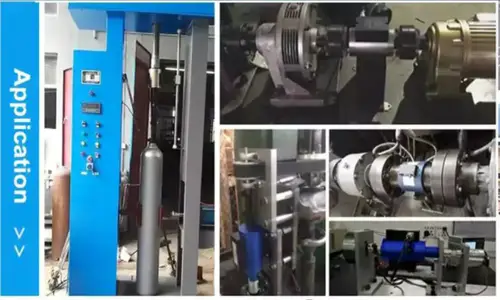

Application of Rigid Shaft Coupling

Rigid shaft coupling has a wide range of applications in various fields. In the Machining Equipment industry, it is used in machine tools, lathes, and drilling machines. In Conveyor Systems, it is used in belt conveyors, chain conveyors, and roller conveyors. In Robotic Systems, it is used in industrial robots and automatic assembly lines. In Pumps and Fans, it is used in centrifugal pumps and axial fans. In Power Transmission, it is used in gearboxes and reducers.

Future Development Trends and Opportunities of Rigid Shaft Coupling Products

The future development trend of rigid shaft coupling products is to improve the performance and reliability of the products, and to meet the needs of various industries for high-precision transmission systems. With the development of new materials and new technologies, the application fields of rigid shaft coupling will become wider and wider, and the market prospect will be very broad.

How to Choose a Suitable Rigid Shaft Coupling

When choosing a rigid shaft coupling, several aspects should be analyzed. Firstly, the torque requirements of the equipment should be considered. Secondly, the misalignment tolerance of the coupling should be consistent with the requirements of the equipment. Thirdly, the operational speed of the equipment should be taken into account. Fourthly, the environmental conditions of the equipment should be considered. Finally, the space constraints and installation requirements of the equipment should be analyzed comprehensively.

Summary

In summary, rigid shaft coupling is an important component in high-precision transmission systems. It has many excellent performance characteristics and can be made of different materials. Rigid shaft coupling has a wide range of applications in various fields such as Machining Equipment, Conveyor Systems, Robotic Systems, Pumps and Fans, and Power Transmission. In the future, with the development of new materials and new technologies, the market prospect of rigid shaft coupling products will be very broad.

Author: Dream